Phm Group

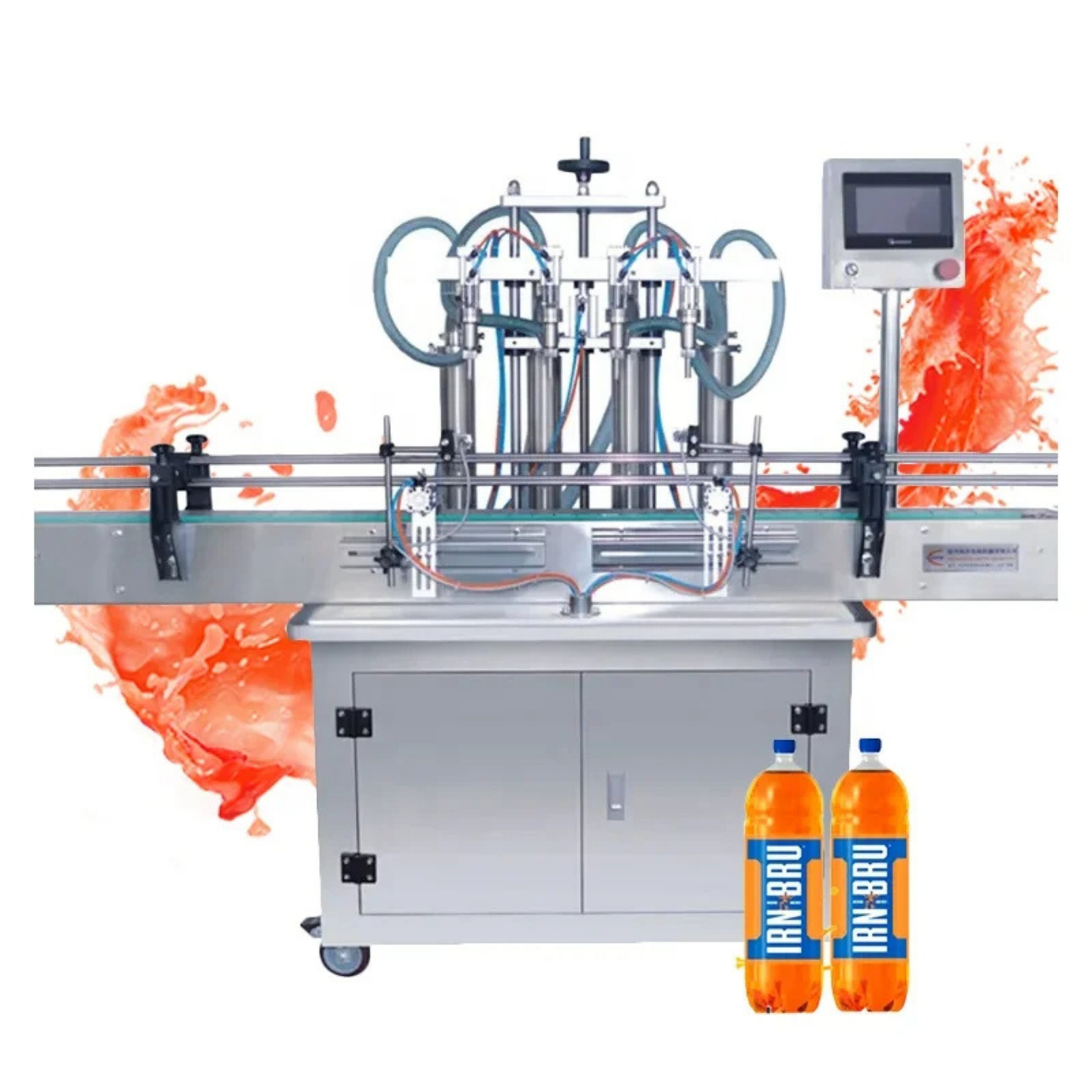

Système professionnel de remplissage et de bouchage automatique de bouteilles PET à 4 têtes

Système professionnel de remplissage et de bouchage automatique de bouteilles PET à 4 têtes

Cet article est expédié depuis l'Asie et son délai de livraison est estimé entre 65 et 75 jours. Nous vous remercions de votre patience et de votre compréhension.

Impossible de charger la disponibilité du service de retrait

Fast Shipping

Free Return

Secure Packaging

100% Original Products

PCI DSS Compliance

ISO 27001 Certified

Dominez la ruée vers l'embouteillage au Cameroun, sans les pannes

Sentez-vous la sueur couler dans votre cou tandis que le bissap se répand sur le sol de votre usine de Douala ? Encore 500 bouteilles perdues par une capsuleuse bancale pendant que les vendeuses attendent ? Au Cameroun, chaque minute d'arrêt vole de la nourriture à votre famille. Notre remplisseuse-boucheuse automatique PET à 4 têtes n'est pas une camelote importée, mais votre armure testée pour le ragoût de ndolé contre les surtensions et l'humidité de Yaoundé. Imaginez : quatre buses en acier inoxydable remplissent parfaitement la bière de gingembre à 120 bouteilles par minute sous les pics brumeux de Buéa, puis clac ! Des capsules hermétiques scellent la fraîcheur du Marché Mokolo, même en cas de baisse de tension.

Pourquoi faire confiance aux importations fragiles ? Conçu pour la réalité camerounaise, il est équipé de stabilisateurs de tension intégrés, de joints anticorrosion et d'une transition 30 % plus rapide entre le vin de palme et l'eau pure, réduisant ainsi les déchets de 40 % et les coûts de main-d'œuvre de 55 %. Contrairement aux machines européennes qui suffoquent sous la chaleur de Douala, notre système PET de qualité alimentaire est rentabilisé en 6 mois grâce aux lots récupérés et à l'absence de défaillance de bouchage. C'est votre solution économique pour approvisionner tous les marchés, de Bamenda à Kribi.

Arrêtez de supplier les générateurs de vous laisser tranquilles. Commencez à mettre en bouteille avec le courage camerounais. Protégez votre héritage : commandez votre système incassable dès aujourd'hui. Nkà !

| Attribut clé | Spécification |

|---|---|

| Matériaux de construction | Acier inoxydable 304 de qualité alimentaire |

| Capacité de production | 1 800 à 2 400 bouteilles/heure |

| Compatibilité des bouteilles | Bouteilles en PET (50 ml à 1 500 ml) |

| Précision de remplissage | ± 0,5 % (contrôle volumétrique) |

| Exigences d'alimentation | 380 V, 50/60 Hz, triphasé |

| Mode opératoire | Automatique (système de contrôle PLC) |

| Caractéristiques spéciales | Hauteur réglable, pas de bouteille, pas de remplissage, système CIP |

| Applications | Production d'eau, de jus et de boissons gazeuses |

|

Type de bouteille

|

Bouteille ronde |

| Source de gaz | 0,5-0,8 Mpa |

| Buses de remplissage | 2/4/6/ Buses |

Partager